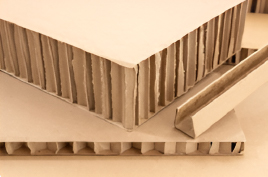

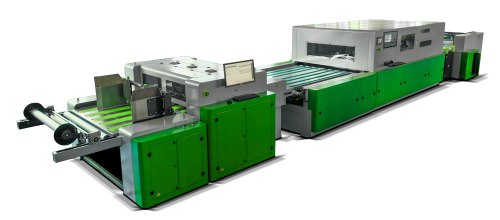

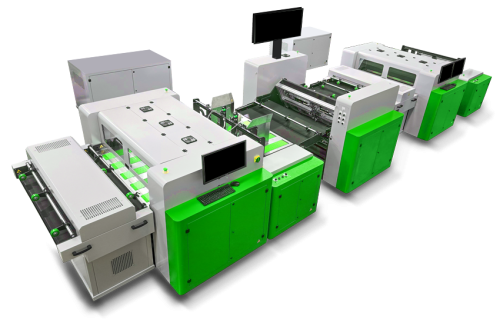

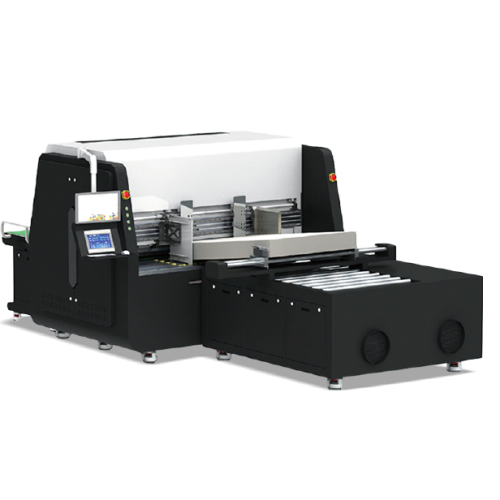

Corrugated Box Making Machine

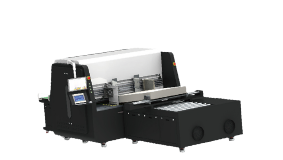

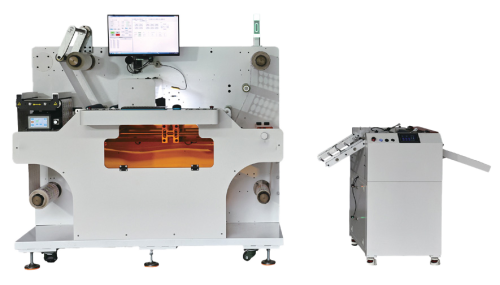

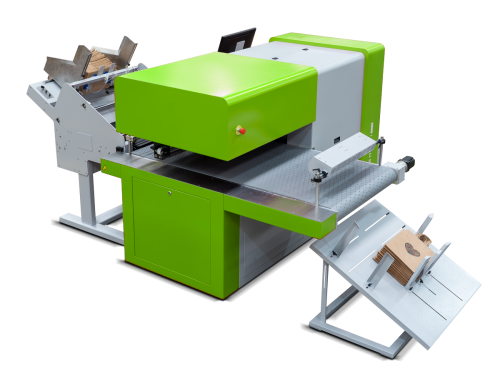

DGP4216

Small Size High Speed Corru-

gated Digital Printing Machine

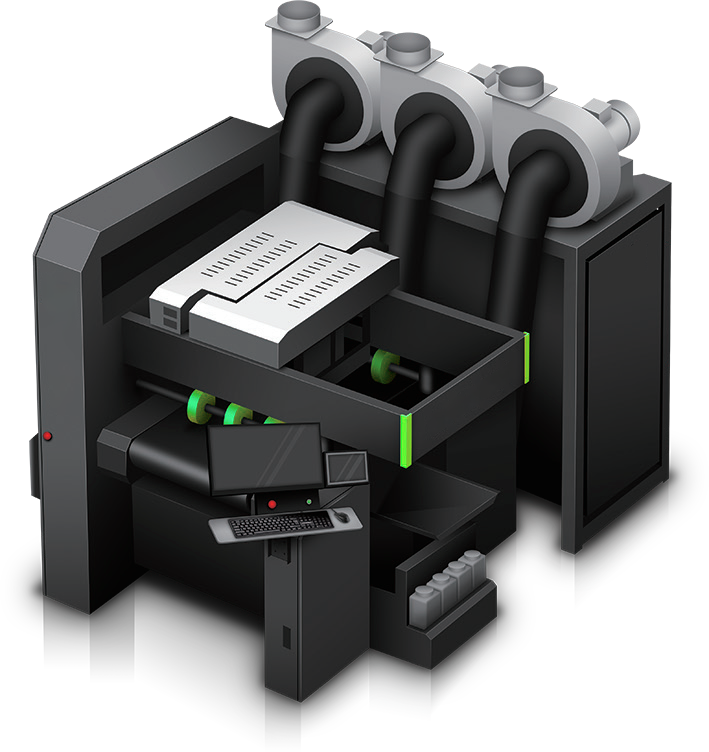

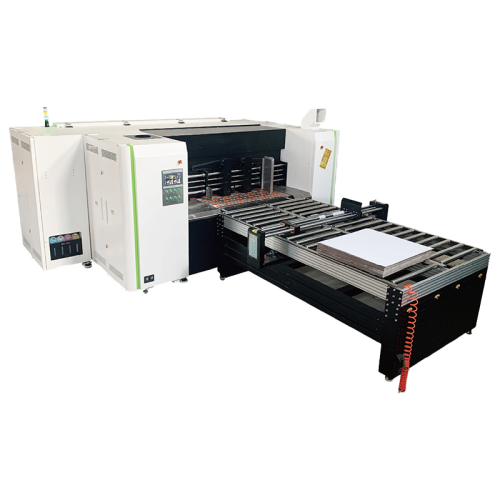

- Water-based pigment ink (waterproof ink) requires no lamination/varnish,resistant to water, sunlight, and abrasion.

- High-frequency ink droplet ejection and coverage capability, nearly eliminating streaking and white gaps.

- OEM Custom

- Fast And Safe Logistics